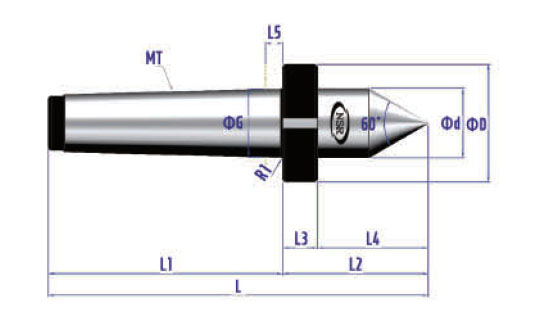

MT Series

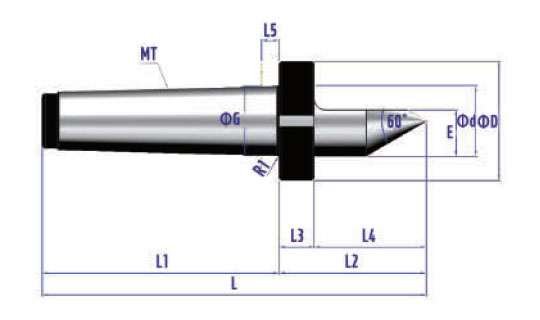

DEAD CENTER

MT-Series

- Possible buying the detachable nut

- Run out-Max 0.002㎜

NSR-MT TYPE

- Heat treatment hardness of center axis, HRC 58~62

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Run Out(mm) |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ||||

| 1009002 | MT2 | MT2 | 40 | 18 | 110 | 67 | 43 | 13 | 30 | 5 | 0.002 |

| 1009003 | MT3 | MT3 | 46 | 24 | 138 | 85 | 53 | 14 | 39 | 6 | 0.002 |

| 1009004 | MT4 | MT4 | 54 | 32 | 175 | 108 | 67 | 16 | 51 | 8 | 0.002 |

| 1009005 | MT5 | MT5 | 75 | 45 | 271.5 | 129.5 | 88 | 20 | 68 | 8 | 0.002 |

| 1009006 | MT6 | MT6 | 97 | 64 | 296 | 189 | 107 | 28 | 79 | 10 | 0.002 |

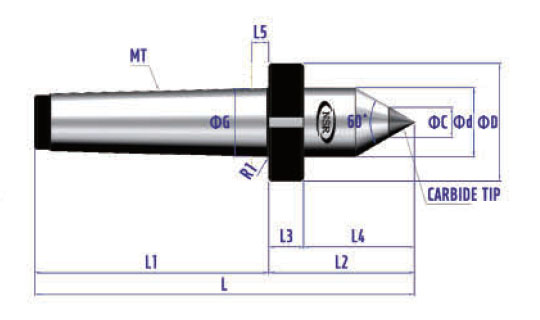

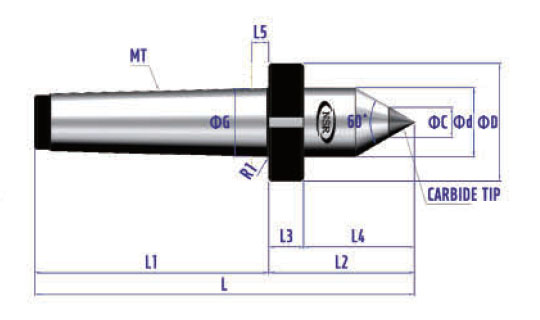

NSR-MTC TYPE

- Heat treatment hardness of center axis

- Hardness of the tungsten cadmium alloy (=tungalloy) HRA 90~91

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Run Out(mm) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ΦC | ||||

| 1009012 | MTC2 | MT2 | 40 | 18 | 110 | 67 | 43 | 13 | 30 | 5 | 10 | 0.002 |

| 1009013 | MTC3 | MT3 | 46 | 24 | 138 | 85 | 53 | 14 | 39 | 6 | 10 | 0.002 |

| 1009014 | MTC4 | MT4 | 54 | 32 | 175 | 108 | 67 | 16 | 51 | 8 | 14 | 0.002 |

| 1009015 | MTC5 | MT5 | 75 | 45 | 271.5 | 129.5 | 88 | 20 | 68 | 8 | 18 | 0.002 |

| 1009016 | MTC6 | MT6 | 97 | 64 | 296 | 189 | 107 | 28 | 79 | 10 | 30 | 0.002 |

NSR-MTH TYPE

- Minimized the interference of whetstone

- Heat treatment hardness of center axis, HRC 58~62

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Run Out(mm) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | E | ||||

| 1009022 | MTH2 | MT2 | 40 | 18 | 110 | 67 | 43 | 13 | 30 | 5 | 11 | 0.002 |

| 1009023 | MTH3 | MT3 | 46 | 24 | 138 | 85 | 53 | 14 | 39 | 6 | 15 | 0.002 |

| 1009024 | MTH4 | MT4 | 54 | 32 | 175 | 108 | 67 | 16 | 51 | 8 | 21 | 0.002 |

| 1009025 | MTH5 | MT5 | 75 | 45 | 271.5 | 129.5 | 88 | 20 | 68 | 8 | 29.4 | 0.002 |

NSR-MTHC TYPE

- Minimized the interference of whetstone

- Minimized the wear property by inserting tungsten cadmum alloy(=tungalloy) to center position

- Hardness of the tungsten cadmium alloy (=tungalloy) HRA 90~91

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Run Out(mm) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | E | ΦC | ||||

| 1009032 | MTHC2 | MT2 | 40 | 18 | 110 | 67 | 43 | 13 | 30 | 5 | 11 | 10 | 0.002 |

| 1009033 | MTHC3 | MT3 | 46 | 24 | 138 | 85 | 53 | 14 | 39 | 6 | 15 | 10 | 0.002 |

| 1009034 | MTHC4 | MT4 | 54 | 32 | 175 | 108 | 67 | 16 | 51 | 8 | 21 | 14 | 0.002 |

| 1009035 | MTHC5 | MT5 | 75 | 45 | 271.5 | 129.5 | 88 | 20 | 68 | 8 | 29.4 | 18 | 0.002 |