LP Series

Low Cast Rotation Center for CN Machining

LP-Series

- Low cost rotation center for CNC machining

- Special oil seal adopted to prevent penetration by coolant and foreign matter

- Run out-Max 0.003㎜

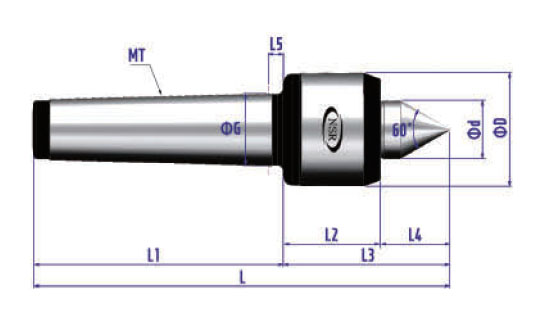

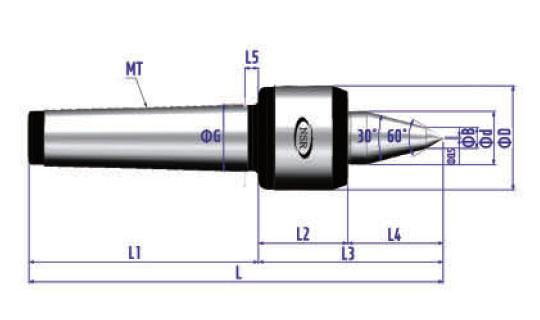

NSR-LP TYPE

- Heat treatment hardness of center axis, HRC 58~62

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ||||||

| 1014004 | 4LP | MT4 | 49 | 25 | 180 | 108 | 42 | 72 | 30 | 6.5 | 500 | 5,000 | 0.003 |

| 1014005 | 5LP | MT5 | 66 | 31.4 | 229 | 136 | 53 | 93 | 40 | 6.5 | 800 | 3,800 | 0.003 |

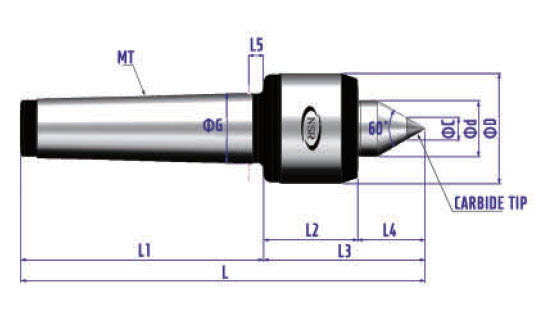

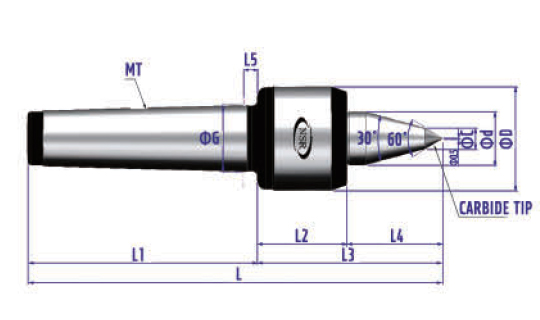

NSR-LPC TYPE

- Minimized the wear property by inserting tungsten cadmium alloy (=tungalloy) to center position.

- Hardness of the tungsten cadmuim alloy (=tungalloy) HRA 90~91

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ΦC | ||||||

| 1014014 | 4LPC | MT4 | 49 | 25 | 180 | 108 | 42 | 72 | 30 | 6.5 | 10 | 500 | 5,000 | 0.003 |

| 1014015 | 5LPC | MT5 | 66 | 31.4 | 229 | 136 | 53 | 93 | 40 | 6.5 | 14 | 800 | 3,800 | 0.003 |

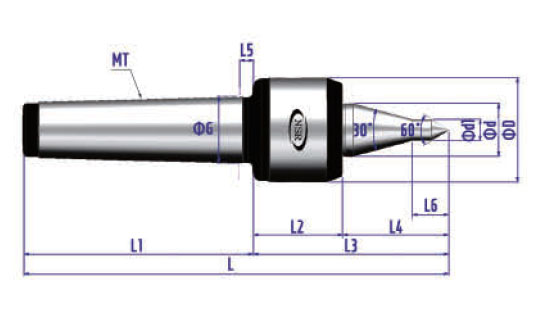

NSR-LPA TYPE

- To minimize the interference of bite

- Heat treatment hardness of center axis, HRC 58~62

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ΦB | ||||||

| 1014024 | 4LPA | MT4 | 49 | 25 | 180 | 108 | 42 | 72 | 30 | 6.5 | 10 | 500 | 5,000 | 0.003 |

| 1014025 | 5LPA | MT5 | 66 | 31.4 | 229 | 136 | 53 | 93 | 40 | 6.5 | 14 | 500 | 3,800 | 0.003 |

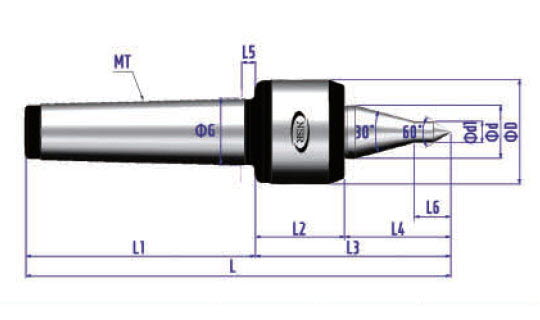

NSR-LPAC TYPE

- To minimize the interference of bite

- Minimized the wear property by inserting tungsten admium alloy (=tungalloy) to center position.

- Hardness of the tungsten cadmium alloy (=tungalloy) HRA 90~91

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ΦC | ||||||

| 1014034 | 4LPAC | MT4 | 49 | 25 | 180 | 108 | 42 | 72 | 30 | 6.5 | 10 | 500 | 5,000 | 0.003 |

| 1014035 | 4LPAC | MT5 | 66 | 31.4 | 229 | 136 | 53 | 93 | 40 | 6.5 | 14 | 500 | 3,800 | 0.003 |

NSR-LPAL TYPE

- To minimize the interference of bite

- Heat treatment hardness of center axis, HRC 58~62

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | L6 | Φd1 | ||||||

| 1014044 | 4LPAL | MT4 | 49 | 25 | 180 | 108 | 42 | 72 | 30 | 6.5 | 17 | 10 | 500 | 5,000 | 0.003 |

| 1014045 | 5LPAL | MT5 | 66 | 31.4 | 229 | 136 | 53 | 93 | 40 | 6.5 | 18 | 12 | 500 | 3,800 | 0.003 |

NSR-LPALC TYPE

- To minimize the interference of bite

- Minimized the wear property by inserting tungsten admium alloy (=tungalloy) to center position.

- Hardness of the tungsten cadmium alloy (=tungalloy) HRA 90~91

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | L6 | ΦC | ||||||

| 1001054 | 4LPALC | MT4 | 49 | 25 | 180 | 108 | 42 | 72 | 30 | 6.5 | 17 | 10 | 500 | 5,000 | 0.003 |

| 1001055 | 5LPALC | MT5 | 66 | 31.4 | 229 | 136 | 53 | 93 | 40 | 6.5 | 18 | 12 | 500 | 3,800 | 0.003 |