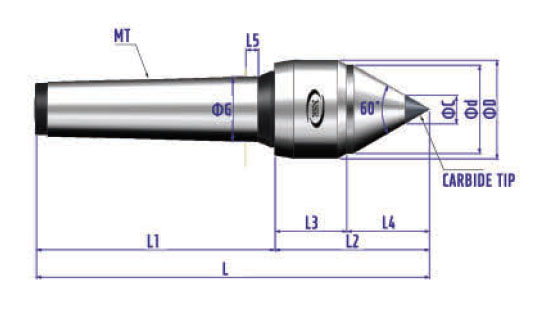

WN Series

For High-speed Rotation | Waterproof Type

WN-Series

- HEAD rotation type

- Minimized the body for reducing the bite-interference

- Run out-Max 0.003㎜

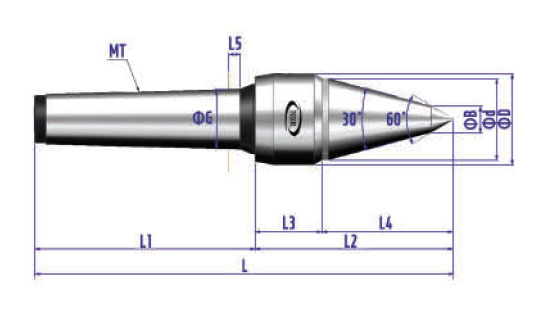

NSR-WN TYPE

- Heat treatment hardness of center axis, HRC 58~62

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ||||||

| 1004002 | 2WN | MT2 | 30 | 27 | 123 | 75 | 48 | 22 | 26 | 4.5 | 200 | 4,000 | 0.003 |

| 1004003 | 3WN | MT3 | 35 | 32 | 144.2 | 89 | 55.2 | 25 | 30.2 | 5 | 400 | 3,000 | 0.003 |

| 1004004 | 4WN | MT4 | 48 | 43 | 191 | 116 | 75 | 35 | 40 | 6 | 700 | 3,000 | 0.003 |

| 1004005 | 5WN | MT5 | 62 | 57 | 238 | 144 | 94 | 40.4 | 53.6 | 8 | 1,300 | 2,000 | 0.003 |

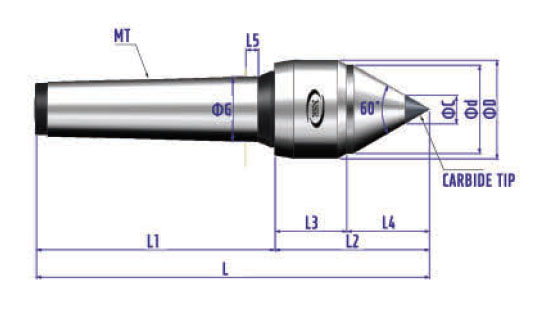

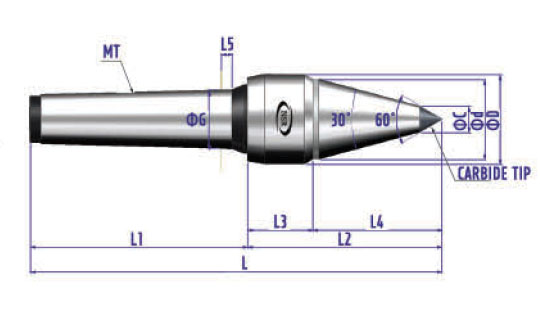

NSR-WNC TYPE

- Minimized the wear property by inserting tungsten admium alloy (=tungalloy) to center position.

- Hardness of the tungsten cadmuim alloy (=tungalloy) HRA 90~91

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ΦC | ||||||

| 1004012 | 2WNC | MT2 | 30 | 27 | 123 | 75 | 48 | 22 | 26 | 4.5 | 10 | 200 | 4,000 | 0.003 |

| 1004013 | 3WNC | MT3 | 35 | 32 | 144.2 | 89 | 55.2 | 25 | 30.2 | 5 | 10 | 400 | 3,000 | 0.003 |

| 1004014 | 4WNC | MT4 | 48 | 43 | 191 | 116 | 75 | 35 | 40 | 6 | 14 | 700 | 3,000 | 0.003 |

| 1004015 | 5WNC | MT5 | 62 | 57 | 238 | 144 | 94 | 40.4 | 53.6 | 8 | 18 | 1,300 | 2,000 | 0.003 |

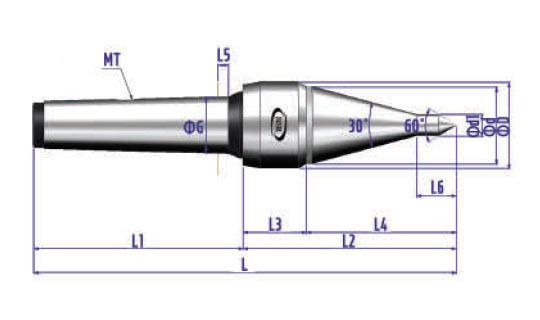

NSR-WNA TYPE

- Second step-angle application for minimize the bite-interference

- Heat treatment hardness of center axis, HRC 58~62

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ΦB | ||||||

| 1004022 | 2WNA | MT2 | 30 | 27 | 140 | 75 | 65 | 22 | 43 | 4.5 | 10 | 120 | 4,000 | 0.003 |

| 1004023 | 3WNA | MT3 | 35 | 32 | 168 | 89 | 79 | 25 | 54 | 5 | 10 | 320 | 3,000 | 0.003 |

| 1004024 | 4WNA | MT4 | 48 | 43 | 220 | 116 | 104 | 35 | 69 | 6 | 14 | 550 | 3,000 | 0.003 |

| 1004025 | 5WNA | MT5 | 62 | 57 | 279 | 144 | 135 | 40.4 | 94.6 | 8 | 16 | 1,000 | 2,000 | 0.003 |

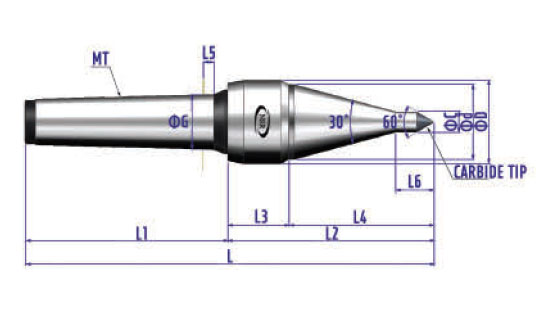

NSR-WNAC TYPE

- Second step-angle application for minimize the bite-interference

- Minimized the wear property by inserting tungsten admium alloy (=tungalloy) to center position.

- Hardness of the tungsten cadmium alloy (=tungalloy) HRA 90~91

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ΦC | ||||||

| 1004032 | 2WNAC | MT2 | 30 | 27 | 140 | 75 | 65 | 22 | 43 | 4.5 | 10 | 120 | 4,000 | 0.003 |

| 1004033 | 3WNAC | MT3 | 35 | 32 | 168 | 89 | 79 | 25 | 54 | 5 | 10 | 320 | 3,000 | 0.003 |

| 1004034 | 4WNAC | MT4 | 48 | 43 | 220 | 116 | 104 | 35 | 69 | 6 | 14 | 550 | 3,000 | 0.003 |

| 1004035 | 5WNAC | MT5 | 62 | 57 | 279 | 144 | 135 | 40.4 | 94.6 | 8 | 16 | 1,000 | 2,000 | 0.003 |

NSR-WNAL TYPE

- Heat treatment hardness of center axis, HRC 58~62

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | L6 | Φd1 | ||||||

| 1004042 | 2WNAL | MT2 | 30 | 27 | 143.8 | 75 | 68.8 | 22 | 46.8 | 4.5 | 12 | 10 | 100 | 4,000 | 0.003 |

| 1004043 | 3WNAL | MT3 | 35 | 32 | 172 | 89 | 83 | 25 | 58 | 5 | 14 | 10 | 280 | 3,000 | 0.003 |

| 1004044 | 4WNAL | MT4 | 48 | 43 | 234 | 116 | 118 | 35 | 83 | 6 | 22 | 12 | 500 | 3,000 | 0.003 |

| 1004045 | 5WNAL | MT5 | 62 | 57 | 294.4 | 144 | 150.4 | 40.4 | 110 | 8 | 21.4 | 12 | 900 | 2,000 | 0.003 |

NSR-WNALC TYPE

- Minimized the wear property by inserting tungsten admium alloy (=tungalloy) to center position.

- Hardness of the tungsten cadmium alloy (=tungalloy) HRA 90~91

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | L6 | ΦC | ||||||

| 1004052 | 2WNALC | MT2 | 30 | 27 | 143.8 | 75 | 68.8 | 22 | 46.8 | 4.5 | 12 | 10 | 100 | 4,000 | 0.003 |

| 1004053 | 3WNALC | MT3 | 35 | 32 | 172 | 89 | 83 | 25 | 58 | 5 | 14 | 10 | 280 | 3,000 | 0.003 |

| 1004054 | 4WNALC | MT4 | 48 | 43 | 234 | 116 | 118 | 35 | 83 | 6 | 22 | 12 | 500 | 3,000 | 0.003 |

| 1004055 | 5WNALC | MT5 | 62 | 57 | 294.4 | 144 | 150.4 | 40.4 | 110 | 8 | 21.4 | 12 | 900 | 2,000 | 0.003 |