SR Series

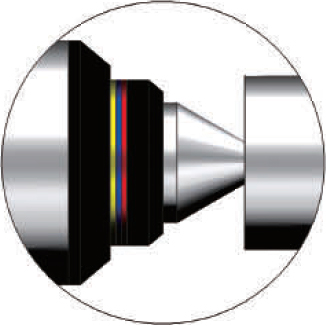

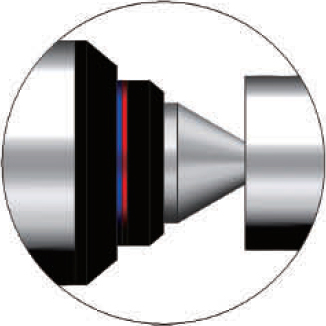

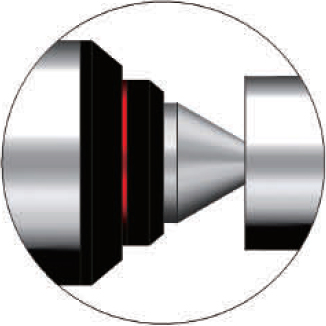

Tailstock Pressure Display Type

SR-Series

- You can easily tell the support of a workpiece.

- When used wigh a face driver, it is possivle to minimize.

- Run out-Max 0.003㎜

-

LOW Pressure

-

Medium Pressure

-

High Pressure

Point Exchangeable Center

Scroll Left / Right

| Color | 2SR | 3SR | 4SR | 5SR |

|---|---|---|---|---|

| YELLOW | 0~500kgf | 0~500kgf | 0~1,000kgf | 0~1,500kgf |

| BLUE | 500~1,500kgf | 500~1,500kgf | 1,000~2,000kgf | 1,500~2,000kgf |

| RED | 1,500~2,500kgf | 1,500~2,500kgf | 2,000~3,000kgf | 3,000~4,500kgf |

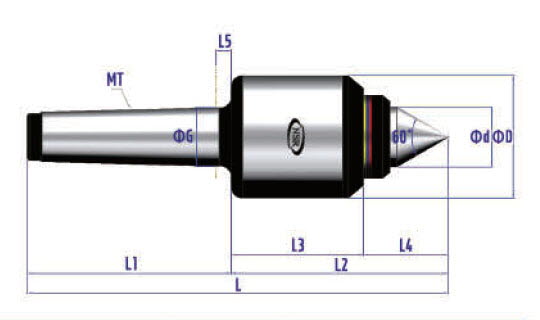

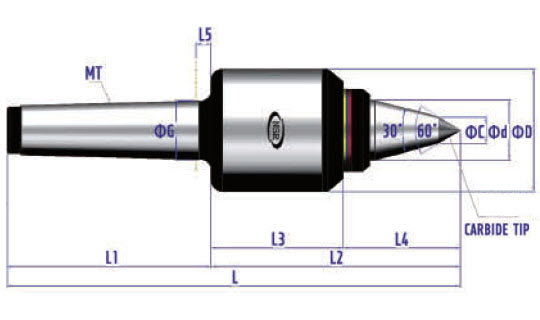

NSR-SR TYPE

- Heat treatment hardness of center axis, HRC 58~62

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ||||||

| 1001502 | 2SR | MT2 | 50 | 25 | 155 | 68 | 87 | 52.6 | 34.4 | 6 | 400 | 5,000 | 0.003 |

| 1001503 | 3SR | MT3 | 50 | 25 | 172 | 85 | 87 | 52.6 | 34.4 | 6 | 700 | 5,000 | 0.003 |

| 1001504 | 4SR | MT4 | 65 | 32 | 223 | 108 | 115 | 70 | 45 | 8 | 1,200 | 3,000 | 0.003 |

| 1001505 | 5SR | MT5 | 94 | 55 | 294 | 136 | 158 | 88 | 70 | 8 | 2,000 | 2,000 | 0.003 |

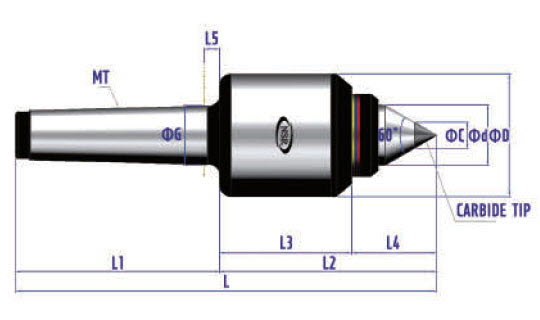

NSR-SRC TYPE

- Minimized the wear property by inserting tungsten admium alloy (=tungalloy) to center position.

- Hardness of the tungsten cadmuim alloy (=tungalloy) HRA 90~91

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ΦC | ||||||

| 1001512 | 2SRC | MT2 | 50 | 25 | 155 | 68 | 87 | 52.6 | 34.4 | 6 | 10 | 400 | 5,000 | 0.003 |

| 1001513 | 3SRC | MT3 | 50 | 25 | 172 | 85 | 87 | 52.6 | 34.4 | 6 | 10 | 700 | 5,000 | 0.003 |

| 1001514 | 4SRC | MT4 | 65 | 32 | 223 | 108 | 115 | 70 | 45 | 8 | 14 | 1,200 | 3,000 | 0.003 |

| 1001515 | 5SRC | MT5 | 94 | 55 | 294 | 136 | 158 | 88 | 70 | 8 | 18 | 2,000 | 2,000 | 0.003 |

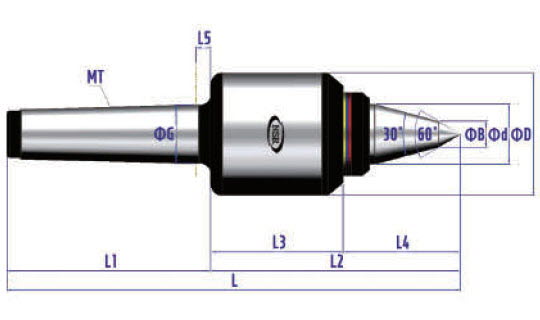

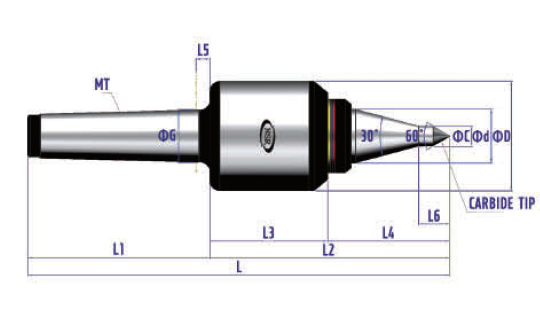

NSR-SRA TYPE

- Second step-angle application for minimize the bite-interference

- Heat treatment hardness of center axis, HRC 58~62

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ΦB | ||||||

| 1001522 | 2SRA | MT2 | 50 | 25 | 172 | 168 | 104 | 52.6 | 51.4 | 6 | 10 | 320 | 5,000 | 0.003 |

| 1001523 | 3SRA | MT3 | 50 | 25 | 189 | 85 | 104 | 52.6 | 51.4 | 6 | 10 | 560 | 5,000 | 0.003 |

| 1001524 | 4SRA | MT4 | 65 | 32 | 240 | 108 | 132 | 70 | 62 | 8 | 14 | 960 | 3,000 | 0.003 |

| 1001525 | 5SRA | MT5 | 94 | 55 | 329 | 136 | 193 | 88 | 105 | 8 | 18 | 1,600 | 2,000 | 0.003 |

NSR-SRAC TYPE

- Second step-angle application for minimize the bite-interference

- Minimized the wear property by inserting tungsten admium alloy (=tungalloy) to center position.

- Hardness of the tungsten cadmium alloy (=tungalloy) HRA 90~91

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ΦC | ||||||

| 1001532 | 2SRAC | MT2 | 50 | 25 | 172 | 68 | 104 | 52.6 | 51.4 | 6 | 10 | 320 | 5,000 | 0.003 |

| 1001533 | 3SRAC | MT3 | 50 | 25 | 189 | 85 | 104 | 52.6 | 51.4 | 6 | 10 | 560 | 5,000 | 0.003 |

| 1001534 | 4SRAC | MT4 | 65 | 32 | 240 | 108 | 132 | 70 | 62 | 8 | 14 | 960 | 3,000 | 0.003 |

| 1001535 | 5SRAC | MT5 | 94 | 55 | 329 | 136 | 193 | 88 | 105 | 8 | 18 | 1,600 | 2,000 | 0.003 |

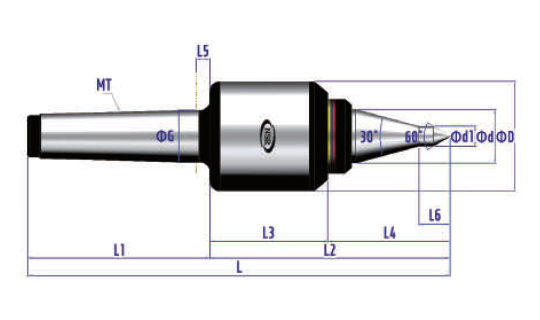

NSR-SRAL TYPE

- Minimized the bite-interference

- Heat treatment hardness of center axis, HRC 58~62

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | L6 | Φd1 | ||||||

| 1001542 | 2SRAL | MT2 | 50 | 25 | 177 | 68 | 109 | 52.6 | 56.4 | 6 | 13.2 | 10 | 320 | 5,000 | 0.003 |

| 1001543 | 3SRAL | MT3 | 50 | 25 | 194 | 85 | 109 | 52.6 | 56.4 | 6 | 13.2 | 10 | 560 | 5,000 | 0.003 |

| 1001544 | 4SRAL | MT4 | 65 | 32 | 250.5 | 108 | 142.5 | 70 | 58.5 | 8 | 18.5 | 12 | 960 | 3,000 | 0.003 |

| 1001545 | 5SRAL | MT5 | 94 | 55 | 344 | 136 | 208 | 88 | 120 | 8 | 22.7 | 14 | 1,600 | 2,000 | 0.003 |

NSR-SRALC TYPE

- Minimized the bite-interference

- Minimized the wear property by inserting tungsten admium alloy (=tungalloy) to center position.

- Hardness of the tungsten cadmium alloy (=tungalloy) HRA 90~91

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | L6 | ΦC | ||||||

| 1001552 | 2SRALC | MT2 | 50 | 25 | 177 | 68 | 109 | 52.6 | 56.4 | 6 | 13.2 | 10 | 320 | 5,000 | 0.003 |

| 1001553 | 3SRALC | MT3 | 50 | 25 | 194 | 85 | 109 | 52.6 | 56.4 | 6 | 13.2 | 10 | 560 | 5,000 | 0.003 |

| 1001554 | 4SRALC | MT4 | 65 | 32 | 250.5 | 108 | 142.5 | 70 | 58.5 | 8 | 18.5 | 12 | 960 | 3,000 | 0.003 |

| 1001555 | 5SRALC | MT5 | 94 | 55 | 344 | 136 | 208 | 88 | 120 | 8 | 22.7 | 14 | 1,600 | 2,000 | 0.003 |